Magnetic separators filter/trap and remove ferromagnetic foreign bodies from your product streams, in order to guarantee high product quality and prevent damage to machines.

Gauss Meter and Pull Test Kit

Gauss Meters measure the number of lines of flux in a magnetic field. This is an accurate measurement of the magnetic field. Used for the verification of magnetic performance as a quality control procedure or for evaluating equipment when considering a performance upgrade.

Pull Testers produce two end results – “PULLING” power and “HOLDING” power. Both of these results are of equal importance. Pulling power relates to the “reach out” of the magnetic field. Holding power relates to the “breakaway force” required to remove the ferrous test fixture from the working surface of the magnet.

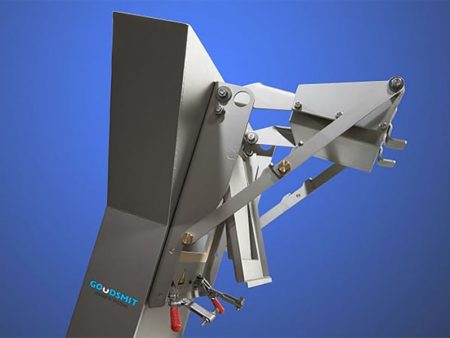

Magnetic Rollers

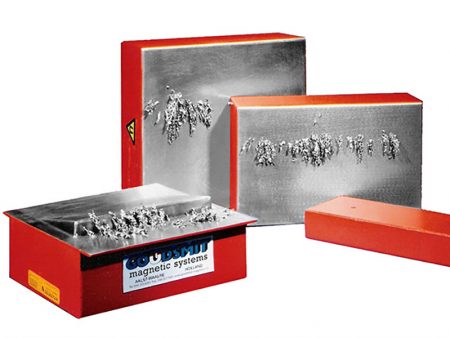

Magnetic chucks use magnetic force to hold a workpiece in place while it is being worked on. Consistent clamping pressure ensures that there is no variation in how tightly or loosely the workpiece is held; full support of the workpiece surface decreases cycle time by securing its center area.

Pot Magnets

Pot magnets are permanent magnets in the shape of a disk wrapped in an iron casing or Zinc plated to avoid damage and obtain greater security in their use. With this combination we obtain an increase in the force of attraction of the magnetized face, at the same time we obtain different types of subjection. They are perfect magnetic solutions for use in small spaces, where a certain magnetic force is required.